Here is a study showing the various failure modes with the keyboard assembly on Roland instruments and synthesizers D-5, D-70, U-20 & JD-800. There are two major areas of failure:

- Interconnect

- Contacts

Summary

It is important to keep these instruments in a damp free environment with keyboard covered when not in use. These keyboard assemblies are pretty fragile and over long periods of time, degrade significantly due to dust, contaminants and corrosion. More importantly, for good velocity pickup, any degradation needs to happen equally on each contact pair.

A bad connection on the interconnect causes groups of keys or intervals of every 8 keys to fail either completely or have bad velocity pickup.

Contact contamination can cause random key failure or poor velocity pickup. Poor velocity pickup is when the “BR” (upper) contact is contaminated or the resistance of it is significantly higher than the “MK” (lower) contact. The scan chip assumes maximum velocity if it doesn’t see the “BR” contact first.

Another problem causing bad velocity pickup is “contact bounce” caused by the “BR” rubber contact having a metal or silver painted surface. It needs to be resistive. Beware of kits that supply little aluminum or gold plated adhesive discs, they don’t work properly on the “BR” contact.

Interconnect

The interconnect between the flexible PCB containing the base contacts can change in conductivity and prevent groups of 8 or intervals every 8 keys from working. With the corrosion that can happen in a damp environment, it is unsurprising that this connection will fail.

The Roland service manual specifically mentions that this should not be disconnected or removed. However, many users have no choice if epoxy glue has run over the flexible PCB. When this fails or becomes disconnected, it is a very challenging fix.

Silver Paint Connection

One method is to use IDC cable and attach using silver paint as shown in the picture below. It is very difficult to undertake.

Separation & Rebond

The picture below shows the damage to the contact surface that happens when simply peeling apart. Some success has been had by using a soldering iron heated to 160 degrees C and melting the plastic very carefully with a gentle pull. See this great article about refurbishment of a JD-800 synthesizer that is in “good condition”, frankly, most are worse than this.

Another potential method of reattachment is to use 3M™ Electrically Conductive Adhesive Transfer

Tape 9703. This tape contains silver particles arranged in a formation such that they conduct only in the z-plane, ansiotropic conductivity.

It is very expensive but short lengths can be obtained from eBay. Some success has been reported on forums and YouTube.

Plastic Clamp

A popular method of fixing the thermal contact issue is to carefully replace the plastic retainer with a clamp and a sponge to apply even pressure to the contacts as shown in the picture below from a modified Roland U-20. A lot of care needs to be taken not to disturb the connections during this process.

Red Death

Apart from the D5, all can suffer from “Red Glue Syndrome” depending on batch number to varying degrees. Many instruments over a long period in the 90’s were affected by poorly mixed epoxy glue used to retain the weight in each key.

It appears slightly soft and moves very slowly eventually dripping out of the key onto either carpet or onto the key contacts if stored with keyboard facing up. Roland attempted to get in touch with all it’s customers who were affected 10 years after purchase, offering a replacement keyboard assembly at their manufacturing cost. In UK, it was offered at 350 GBP in 2003.

JD-800 Center has a lovely instruction on how the red glue is removed with Sodium Hydroxide solution.

Red glue reaching the flexible PCB assembly and rubber contacts is extremely damaging, it may be possible to find a method of cleaning but performance is not likely to be the same again. The effects of it once cleaned off the contacts are not examined here in detail until test samples are available.

Ryan Hull, who is one of the beta testers for the Super Synth Projects replacement flexible PCB, provided these pictures, showing a very sorry state of affairs. The instrument was almost completely ruined, if it were not for very careful refurbishment and cleaning by Ryan. The synth had been stored with keys vertically up, all glue just ran through the instrument!

In earlier flexible PCBs, the red glue can permeate through the top coverlay on the PCB and corrode the traces underneath, as shown in this picture below from a Roland U-20.

Contact Failure

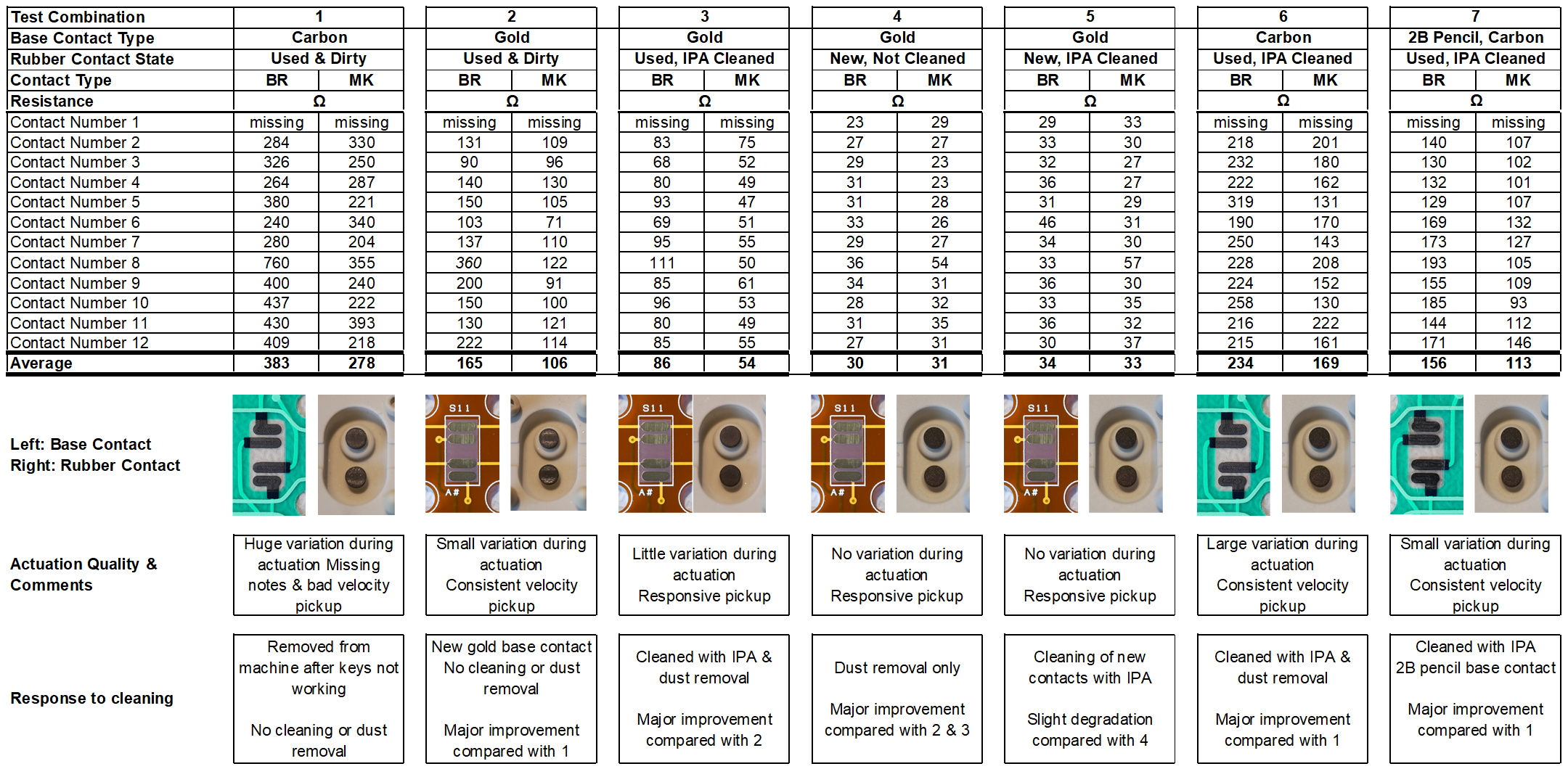

Here is a study of the contact performance in the Roland keyboard assembly used on the following instruments: D5, D70, U20 & JD-800.

Tests & Results

Seven different tests were conducted using different samples, old and new. The primary reason for this testing was to verify the performance of a replacement flexible circuit with gold plated base contacts. However, the tests were extended to include other treatments undertaken by users claiming improvements on various forums, see results on 6 & 7.

These tests only focus on final contact resistance once contact has the correct pressure dictated by the shape and balance point of the rubber contact structure. Over pressure causes increased resistance as well under pressure.

It’s important to note that initial resistance was not measured. At point of contact closure, initial resistance can be a few thousand ohms, as contact pressure increases, resistance lowers and this property is used to clean up the signal when measuring velocity. Resistive properties of the top contact is therefore essential for reliable operation.

Generally performance is affected by:

- Carbon base contacts surface resistivity increases with time if the instrument is not played.

- Dust getting between the contact points

- Oils and contaminants, usually from skin particles

- General wear and tear of contact surface

- Oxidisation of the metal/carbon base contact surface

- Upper contact set “BR” that make first during operation have significantly more resistance than lower “MK” contact

Recommendations

When refurbishing keyboard assemblies they are very fragile and require a clean environment during reassembly. Contact performance can be remedied to various extents by careful cleaning with IPA and dust/surface charge removal using an anti-static brush. Deionised water is also more gentle alternative to IPA if there’s a concern with previous excessive cleaning. Dust, dirt and oils from hands when handling the components are a hazard to the contact quality. These measures if not undertaken may affect the lifetime of the repair, initially works then fails weeks or months later.

A replacement base contact, using a non oxidising metal coating, yielded the very best results and good prognosis for long life.

If applying conductive paint instead, it is vital that only the bottom contact is painted. Resistive properties of the rubber top contact are essential for the switch de-bounce function on velocity sensitive keyboards.

A word of warning for contact cleaning the Roland Flexible PCB, the green coverlay can be removed with IPA. When cleaning carbon contacts they need to be cleaned individually, not together using a IPA soaked cloth rubbed along it’s length. If a wet bud comes into contact with the green coverlay, then the contact will be contaminated by insulating coverlay residue.

Rubber Contact Samples

Pictures below show new and old rubber contact strips, old are obviously with one contact missing.

The old and used contacts were heavily worn and contaminated, they were passed through various stages of treatment before testing.

Picture below shows the contacts with dust and greasy deposits as pulled from the synthesizer, used in tests 1 and 2 to compare the benefits of using carbon or gold plating on the base contacts once the keyboard has worn heavily.

Picture below shows old contacts after cleaning thoroughly with IPA then dust removal with an anti-static brush, as described in tests 3 and 7.

Picture below shows unused contacts that have been in storage for 5 years after purchase. In test 4 they were used after dust removal, test 5 they were cleaned with IPA to see what degradation occurred when removing any carbon coating that might exist. A black deposit did show on the cotton bud during cleaning.

Base Contact Samples

Standard carbon coated key contact on the Roland Flexible PCB used in the keyboard assembly. Used in tests 1 and 6.

Used in test 7, standard carbon coated key contact rubbed with a 2B pencil and then brushed clean., it is possible to see the grains of material left behind even after brushing.

The Super Synth Projects flexible circuit replacement uses gold plating to lower contact resistance, tests 2, 3, 4 and 5. The purpose was to verify the design and assess how it would work in different stages of contact wear.

The reason why a new gold base contact works so well, is because the resistive properties of the top contact are not interfered with. During actuation, as switch pressure increases, contact resistance lowers proportionally and gradually as force increases to the correct level. A resistive top contact retains the switch de-bounce property, a delicate balance of force and resistance.

Adding metal or highly conductive surface to the top contact generates a complex random digital pulse train, known as switch bounce and confusing the keyboard scan chip during velocity measurement.

Worse still, an imbalance of resistance between “BR” and “MK” contacts causes false timing measurements for velocity.

If the “BR” contact is not seen then velocity will be deemed “maximum level” when “MK” is seen thus resulting in a false impression that the keyboard is “working” for many types of patches. Choose your patch carefully when testing.

For velocity sensitive keyboards, using conductive paint to restore contacts doesn’t work on the top contact, it must be applied to the bottom carbon contact and the top rubber contact cleaned thoroughly instead.

If top contact is painted, a very smooth finish will help to reduce bounce but it isn’t completely perfect and variability is noticed by experienced players, some reporting it being “horrible”.

Copyright © 2021 Super Synth Projects, Guy Wilkinson & Jonathan Williams

You must be logged in to post a comment.